Mar 10, 2021

Laser pulse distance measurement in real time (>100 MHz)

Physical Sciences, Measurement Technology, Mechanical Engineering

- unmatched precision and speed in laser processing

- inline laser pulse distance measurement

- based on optics and analog technology

Your contact

Stephan Ottmar

- E-Mail:

- sottmar@baypat.de

- Phone:

- +49 (0) 89 5480177 - 37

- Reference Number:

- B78038

Factsheet

Download Tech Offer (PDF)Challenge

Fast and precise control of processing depths between the laser head and the workpiece limitsthe process speed of a variety of potential micro-laser processing operations for ablation,cutting or structuring. This reduces efficiency.

Current measurement methods, based on white-light interferometry or optical coherencetomography, achieve scan rates in the hertz up to kilohertz range - characteristically aftermachining has been completed or in time-average. However, to accurately modulate orinterrupt exposure, many applications require a shot-to-shot monitoring in real time. Whereverirregular inhomogeneous materials (e.g., organic structures or fiber-reinforced components)are processed with high precision, compromises between accuracy and operating speed limitprocess efficiency. Particularly high demands arise especially in medical eye treatment andskin ablation, but also in battery or solar cell production, where electrical insulation must beablated in a defined manner.

Innovation

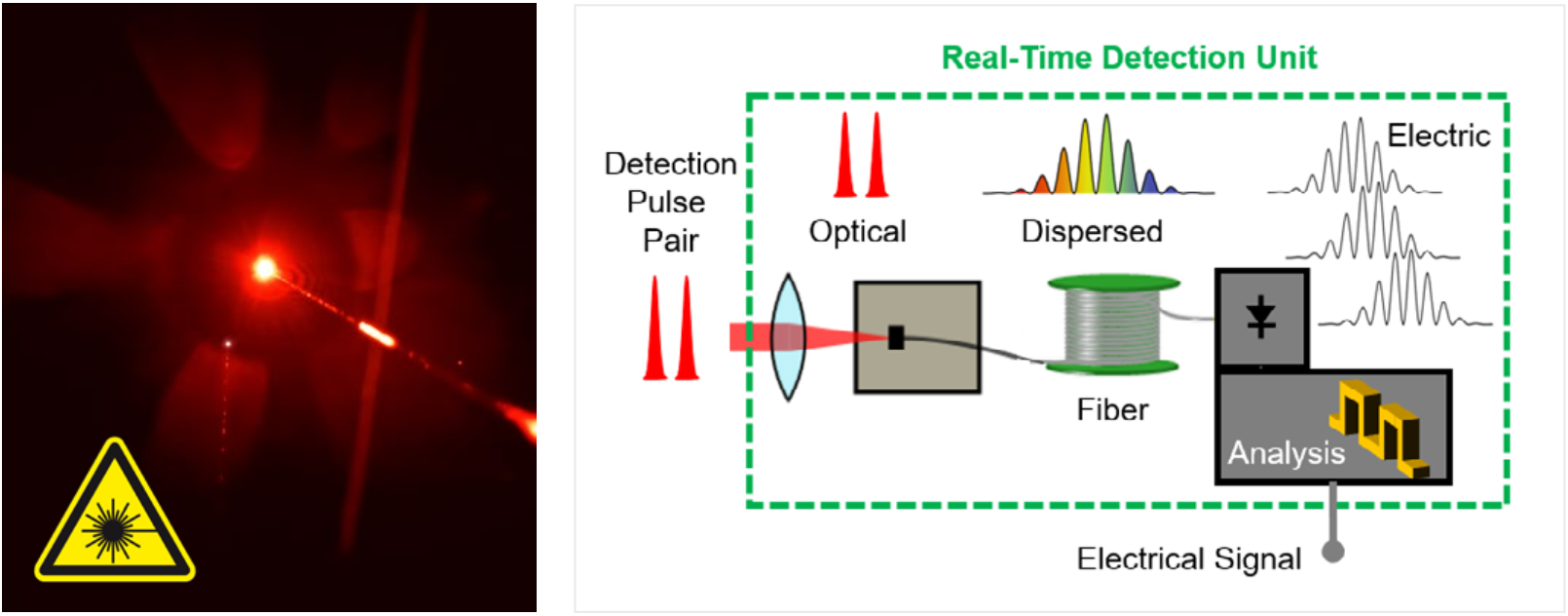

The present invention is based entirely on optics and analog electronics. The process achievesreal-time process control with extraordinary measurement rates up to over 100 MHz. It isbased on spectral interferometry and compares the differences in path lengths in referenceand sample paths. The Dispersive Fourier Transform processes the analog signals at unmatchedspeed. The electrical measurement signal can be directly fed back to change the processingexposure between successive laser shots. The robust technology is based on standardized andcost-effective components.

Commercial Opportunities

The invention enables unprecedented precision and speed in laser processing and microsurgery.Single-shot inspection with real-time feedback enables new processing schemes. Thetechnology allows the use of time-efficient, highly repetitive laser sources, which increasesthe economic efficiency in the process. Areas of application are in the processing of complexand brittle materials with structural inhomogeneity. These include non-contact surfacestraightening and free-forming (individual surface height variability), selective ablation,safety-critical applications in electronics (electrical insulation of batteries or organic electronics)or laser eye treatment. Even moving or vibrating workpieces can be precisely processed.

Development Status

A demonstrator for a laser micromachining application with real-time feedback, based onsingle-shot processing, is currently being implemented. The measurement principle has beensuccessfully proven.