11.05.2022

Backflushable gradient bed filter for particle separation

Physical Sciences, Material

- Increased filtrate yield and separation efficiency

- Enormous cost reduction through low running costs, an optimized backflushing process and the use of glas beads as a cost effective and environmentally friendly filter medium

- Can be easily adapted to the needs of various industrial sectors

Ihr Kontakt

Dr. Katrin Bercht

- E-Mail:

- kbercht@baypat.de

- Telefon:

- +49 (0) 89 5480177 - 16

- Referenznummer:

- B80032

Factsheet

Download Tech Offer (PDF)Herausforderung

The separation of undissolved solids or liquid substances from fluids is a crucial process invarious industrial sectors and domestic needs, in particular for reprocessing and preparation of process liquids, household and industry water or air. A basic distinction is made between surface- and depth filtration systems. For surface filtration, membranes or fabrics with a defined mesh size are used, resulting in a defined separation size. However, depending on the area of application, the production costs for such systems can be relatively high and the clogging behavior poor. In case of depth filtration, the substance is separated deep within the filter medium. Using filter media such as glass spheres makes the production of such systems relatively cost-effective and environmentally friendly, however, there is still a need for optimization of the insufficient backflushing process as well as the separational precision of existing systems.

Innovation

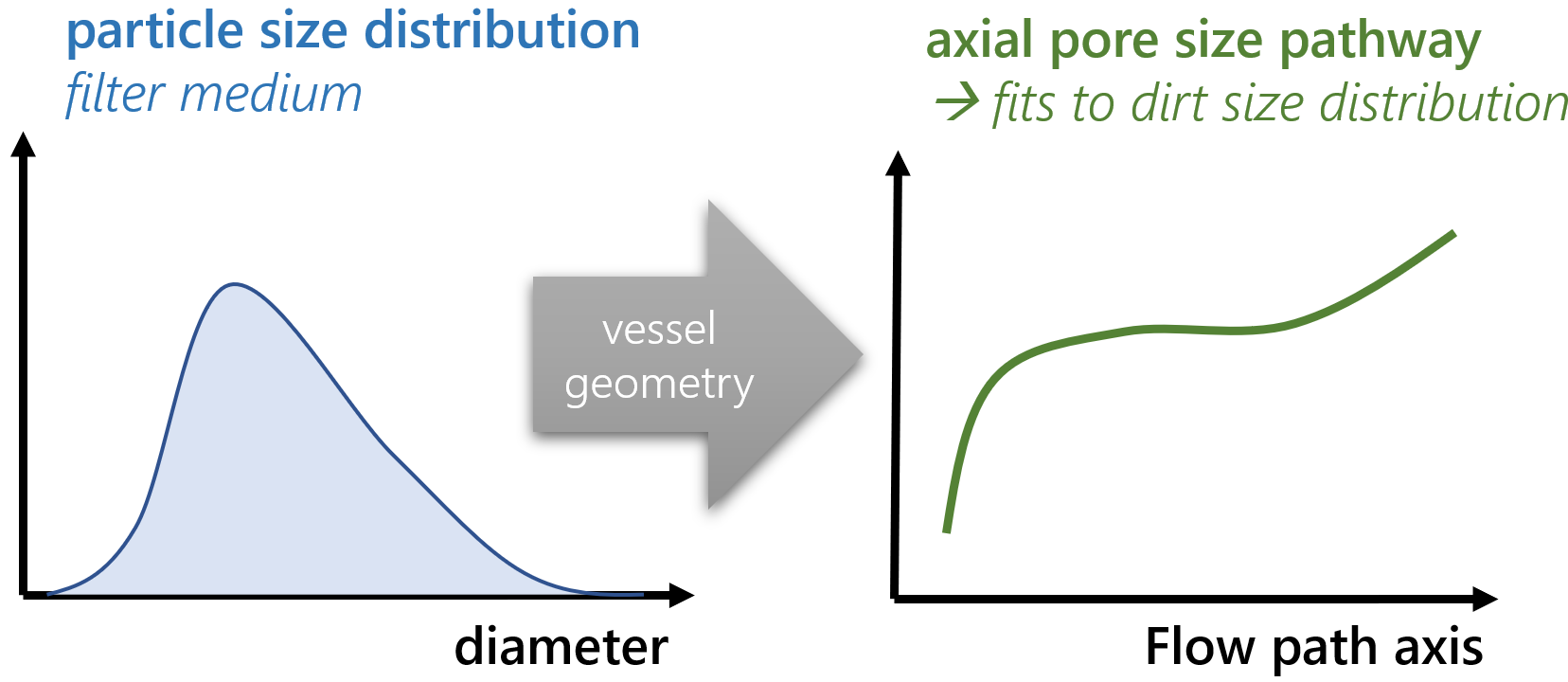

The innovative gradient bed filter system combines the advantages of both principles mentioned above using a spherical filter medium. The fluid to be filtered is guided through the filter medium which is arranged in a sorting in which the particle size varies in the direction of flow. Holding the granulate medium between two perforated plates keeps it in its compact shape even during backflushing.

Advantages over conventional fixed-bed filter systems are the selectivity defined by the sphere diameters and the increased separation efficiency. In addition, the manufacturing process for the filter medium is cost-effective and, due to the possible use of recycled material, environmentally friendly. Furthermore, due to the process stability of the glass beads, the filter system can be applied in all industrial sectors, including the food or pharmaceutical industry.

Kommerzielle Möglichkeiten

Innovative and scalable gradient bed filter system with an optimized backflushing process, and a cost-effective filter medium for an increased filtrate yield and separation efficiency

Entwicklungsstatus

Idea stage

Currently searching for partners for further development and licensing